适用行业

- 汽车

适用功能

- 产品研发

服务

- 软件设计与工程服务

客户

未公开

关于客户

一家汽车制造公司。

挑战

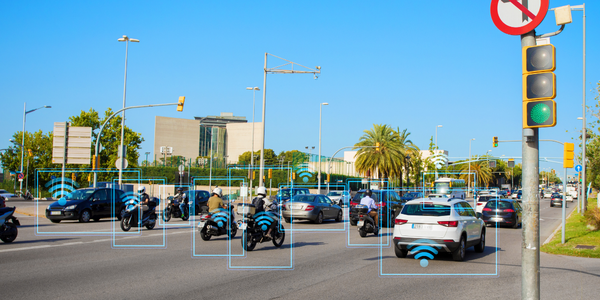

连通性使消费者和公司之间的互动更加智能。一家创新汽车制造商希望设计和构建互联汽车平台的工作原型,以加快上市速度并帮助公司了解当今的互联世界。

解决方案

Flex 的设计团队与汽车制造商的研究人员合作开发规格以满足他们的需求:长电池寿命、全球连接性、模块化平台和强大的天线。 Flex 的电气和机械工程师、工业设计师以及云和软件开发人员组成的跨行业团队创建了一个快速转变的电气和机械设计,包括用于通信的嵌入式技术、用于分析和智能的移动应用程序以及用于数据收集的云存储。软件组件 - Flex 云平台

运营影响

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

Monitoring of Pressure Pumps in Automotive Industry

A large German/American producer of auto parts uses high-pressure pumps to deburr machined parts as a part of its production and quality check process. They decided to monitor these pumps to make sure they work properly and that they can see any indications leading to a potential failure before it affects their process.