技术

- 功能应用 - 库存管理系统

- 功能应用 - 制造执行系统 (MES)

适用行业

- 金融与保险

- 生命科学

适用功能

- 设施管理

- 仓库和库存管理

用例

- 库存管理

- 拣选/分拣/定位

服务

- 系统集成

客户

凯尔图尔控制

关于客户

Keltour Controls专门为成千上万的国内和国际客户制造控制面板。扩展他们的产品,他们现在还在大多数主要行业中设计、设计、集成、编程和调试系统。

挑战

Keltour 有几个他们希望在新系统中解决的关键问题。

时间跟踪限制要求会计和工资单在提交后重新输入工作时间。这导致每周增加几个小时的工作,并导致工作劳动力成本计算和报告滞后一周。

需要更好地跟踪和实时监控他们的制造数据。最后,他们需要与会计数据相关联,以便更好地了解他们的 WIP 和项目发票。

解决方案

Keltour 最初在 18 年前实施了 Total ETO,但使用的是旧版本,不再满足他们的需求。由于不知道多年来对 Total ETO 进行的升级,Keltour 尝试实施另一个系统,但无法使其正常工作。没有数学链接,没有逻辑,也没有供应商支持来帮助解决问题。

回到 Total ETO,他们安装了最新版本。每个人都熟悉并熟悉它,因此很容易再次开始使用。最后,这是一个简单的决定,他们立即看到了流程的改进。

运营影响

数量效益

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

相关案例.

Case Study

Real-time In-vehicle Monitoring

The telematic solution provides this vital premium-adjusting information. The solution also helps detect and deter vehicle or trailer theft – as soon as a theft occurs, monitoring personnel can alert the appropriate authorities, providing an exact location.“With more and more insurance companies and major fleet operators interested in monitoring driver behaviour on the grounds of road safety, efficient logistics and costs, the market for this type of device and associated e-business services is growing rapidly within Italy and the rest of Europe,” says Franco.“The insurance companies are especially interested in the pay-per-use and pay-as-you-drive applications while other organisations employ the technology for road user charging.”“One million vehicles in Italy currently carry such devices and forecasts indicate that the European market will increase tenfold by 2014.However, for our technology to work effectively, we needed a highly reliable wireless data network to carry the information between the vehicles and monitoring stations.”

Case Study

Safety First with Folksam

The competitiveness of the car insurance market is driving UBI growth as a means for insurance companies to differentiate their customer propositions as well as improving operational efficiency. An insurance model - usage-based insurance ("UBI") - offers possibilities for insurers to do more efficient market segmentation and accurate risk assessment and pricing. Insurers require an IoT solution for the purpose of data collection and performance analysis

Case Study

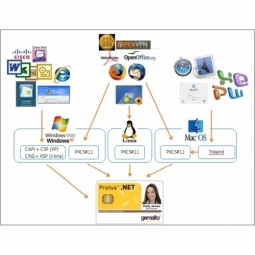

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Smooth Transition to Energy Savings

The building was equipped with four end-of-life Trane water cooled chillers, located in the basement. Johnson Controls installed four York water cooled centrifugal chillers with unit mounted variable speed drives and a total installed cooling capacity of 6,8 MW. Each chiller has a capacity of 1,6 MW (variable to 1.9MW depending upon condenser water temperatures). Johnson Controls needed to design the equipment in such way that it would fit the dimensional constraints of the existing plant area and plant access route but also the specific performance requirements of the client. Morgan Stanley required the chiller plant to match the building load profile, turn down to match the low load requirement when needed and provide an improvement in the Energy Efficiency Ratio across the entire operating range. Other requirements were a reduction in the chiller noise level to improve the working environment in the plant room and a wide operating envelope coupled with intelligent controls to allow possible variation in both flow rate and temperature. The latter was needed to leverage increased capacity from a reduced number of machines during the different installation phases and allow future enhancement to a variable primary flow system.

Case Study

Automated Pallet Labeling Solution for SPR Packaging

SPR Packaging, an American supplier of packaging solutions, was in search of an automated pallet labeling solution that could meet their immediate and future needs. They aimed to equip their lines with automatic printer applicators, but also required a solution that could interface with their accounting software. The challenge was to find a system that could read a 2D code on pallets at the stretch wrapper, track the pallet, and flag any pallets with unread barcodes for inspection. The pallets could be single or double stacked, and the system needed to be able to differentiate between the two. SPR Packaging sought a system integrator with extensive experience in advanced printing and tracking solutions to provide a complete traceability system.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data