Predictive Maintenance

Predictive maintenance is a technique that uses condition-monitoring sensors and Machine Learning or rules based algorithms to track the performance of equipment during normal operation and detect possible defects before they result in failure. Predictive Maintenance enables the reduction of both schedule-based maintenance and unplanned reactive maintenance by triggering maintenance calls based on the actual status of the equipment. IoT relies on Predictive Maintenance sensors to capture information, make sense of it, and identify any areas that need attention. Some examples of using Predictive Maintenance and Predictive Maintenance sensors include vibration analysis, oil analysis, thermal imaging, and equipment observation. Visit our condition-based maintenance page to learn more about these methods.

- Automotive

- Energy

- Equipment & Machinery

- Discrete Manufacturing

- Maintenance

- Quality Assurance

The predictive maintenance market size is estimated to grow from USD 1,404.3 Million in 2016 to USD 4,904.0 Million by 2021, at a Compound Annual Growth Rate (CAGR) of 28.4% during the forecast period.

Source: markets and markets

How does Predictive Maintenance impact an organization’s performance?

Predictive maintenance is often the first use case that is prioritized, and it is seldom the end game. In manufacturing, enabling predictive maintenance provides near term value by improving OEE and reducing maintenance costs. In the longer term, it enables data collection that supports more advanced use cases such as lot size of one or more effective or flexible production line configurations.

In machine building, any time it is proactive rather than reactive, there is an opportunity for value creation- for example, reducing truck rolls (sending out a truck for maintenance) is a cost saving method. In the longer term, it enables data collection that supports more advanced use cases such as asset servitization.

How is the success of Predictive Maintenance measured for users and for the business?

In the airline industry, uptime availability, the number of truck rolls (sending out a field service technician), over the air updates, overall asset maintenance cost and time to availability.

What are the typical capabilities of Predictive Maintenance?

Some of the main capabilities are; accurate data ingestion, communication of data in near real-time (requirements can differ from real-time to daily), conversion of data into algorithms that provide input to guide decisions in reasonable lead time. Other capabilities include the amount of historical data, cleanliness of data, ingestion of new data, legacy footprint in regards to legacy protocols for data communication, data analysis location

Where is the “edge” of the Predictive Maintenance solution deployed?

A wide array of field assets - any high-value equipment that has a high downtime cost either due to loss or productivity or a resulting bottleneck. Applicable to assets ranging from medical diagnostic equipment to agriculture equipment, to wind turbines.

Which organizations, departments, or individuals are responsible for operating and maintaining Predictive Maintenance?

This is contingent upon the situation but tends to be a hybrid solution. Ongoing maintenance of the system can be handled in-house by the corporate IT team or by an external system integrator. The internal or external IT team will own the data flow and infrastructure - gateways, notifications, data flow, updates, etc. The OT team will incorporate system inputs into their operational activities.

Who are the regular users of Predictive Maintenance?

The end user can be the system owner or the system owner can be a machine builder while the end user is the equipment operator.

Which external stakeholders would benefit most from Predictive Maintenance data?

If the operator owns the system they will not share with the machine builder. If the machine builder owns the system they may share data with the operator but will guard their data is possible. Leverage matters but the default decision are to not share data.

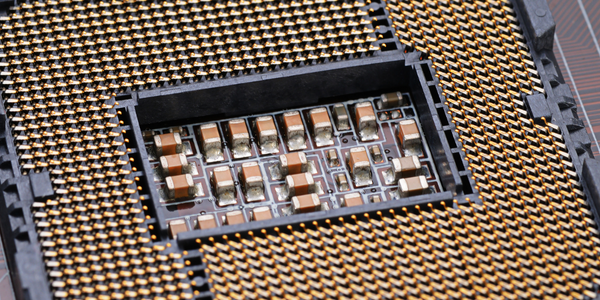

What sensors are typically used to provide Predictive Maintenance data into the IoT system, and which factors define their deployment?

Collecting data is the first step - a wide array of sensors can be selected. The selected sensor depends upon the specific asset and the maintenance objective.

What factors define the interfaces available to system users?

Interfaces can range from standard equipment interfaces to desktop computers, to mobile phones, to augmented reality (AR) solutions. A mobile phone can serve as a low-cost AR device to provide accurate information as needed.

Sensor Data: Sensors collect real-time data on equipment parameters such as temperature, vibration, and operating conditions. This data is analyzed to identify patterns and anomalies that may indicate potential failures or maintenance needs.

Historical Maintenance Records: Historical maintenance records provide valuable insights into equipment performance and failure patterns over time. By analyzing past maintenance activities and their outcomes, predictive maintenance models can be trained to predict future failure scenarios more accurately.

What business challenges could impact Predictive Maintenance deployment?

A considerable amount of historical data must be available. In some cases high quality, useful data is readily available. In many cases, there is limited data or the data is not useful for designing the algorithm. IT capabilities should ideally be available in the customer organization but could also be outsourced.

What integration challenges could impact Predictive Maintenance deployment?

Data sharing is a significant challenge both across companies (almost impossible) and even across equipment owned by one operator due to use of different communication protocols.

What installation challenges could impact Predictive Maintenance deployment?

Deploying in process manufacturing or other facilities that are running 24/7 can be particularly challenging due to the need to install technology without disrupting operations. Green patch solutions that deploy a new system on a specific production line in a larger facility can be effective for establishing value before a large investment. Location can be a challenge in specific environments such as a deep earth mine or an offshore oil rig.

What regulatory challenges could impact Predictive Maintenance deployment?

Regulatory challenges vary greatly by industry. In medical and financial challenges can be significant. Any time data from a medical device is accessed or an external system impacts device operations there will be regulatory implications. The regulatory challenges will vary depending on the application.

Case Studies.