Growth

| Chemicals

Polycarbonate Demand Forecast Modeling

Client

The VP of marketing for the polycarbonate business of a chemical manufacturer believed that weak forecasting accuracy was leading to mis-allocation of volume and unnecessary price discounts.

Situation

A chemical manufacturer suffered from weak demand forecast accuracy. This limited the company’s ability to manage volume allocation across customers. It also led to unnecessary price discounts being offered to customers, which negatively impacts topline revenue and profitability. This is a chronic challenge in the industry since demand can fluctuate significantly from quarter to quarter due to market cycles in customer industries.

The client’s forecasting team was highly reliant on lagging indicators, such as price indices. They believed that a machine learning approach could provide insight into future trends by processing leading indicators that correlate with future demand conditions.

The client’s forecasting team was highly reliant on lagging indicators, such as price indices. They believed that a machine learning approach could provide insight into future trends by processing leading indicators that correlate with future demand conditions.

Approach

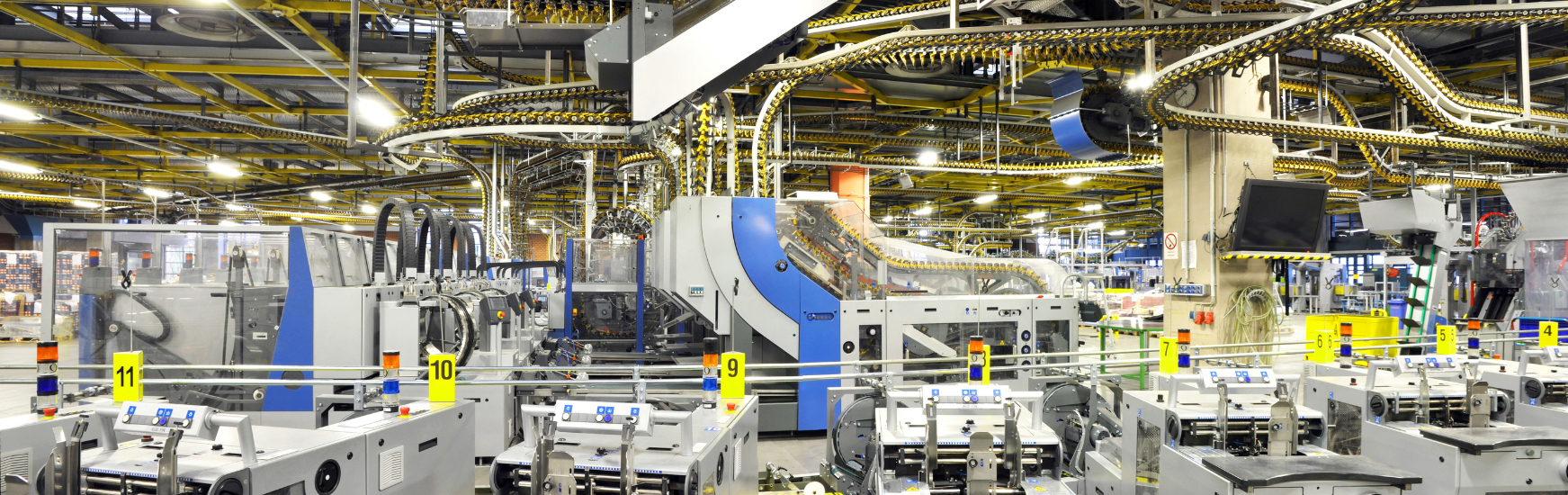

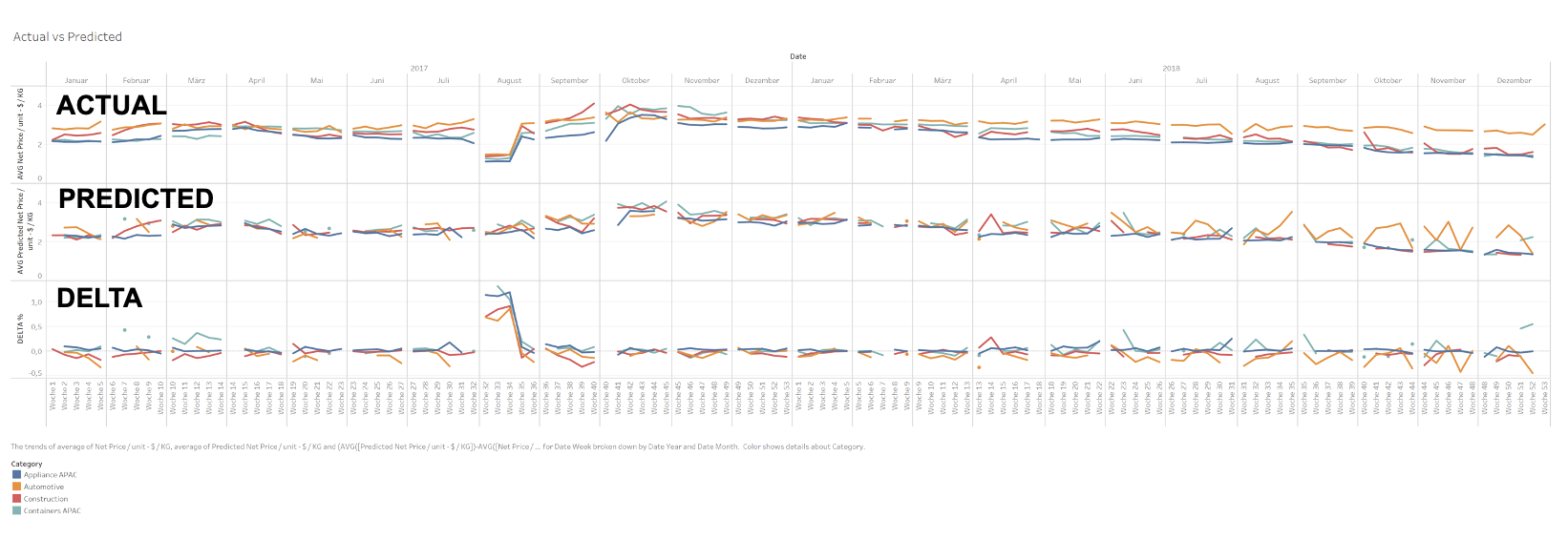

Asia Growth Partners used machine learning frameworks to build an algorithm with the goal of forecasting demand at 2-month, 3-month, and 12-month time horizons. This algorithm was not intended to replace the forecasting team. Instead, it would serve as a tool in their effort to shift from a qualitative to a quantitative demand forecasting approach. The end customer industries included construction, automotive, and consumer electronics.

The algorithm ingested over 1,400 external variables, including macroeconomic indicators, customer industry demand indicators (e.g., housing price indicators in major economies), dates that correlate with demand shifts (e.g., holidays, weather trends), and market data (e.g., energy cost futures). Additionally, over 100 internal variables were considered, ranging from price quotes to time taken to close specific steps of the sales process. Three years of historical data were available from most data sets for training. Random forest and time series models were found to be the most effective.

The algorithm ingested over 1,400 external variables, including macroeconomic indicators, customer industry demand indicators (e.g., housing price indicators in major economies), dates that correlate with demand shifts (e.g., holidays, weather trends), and market data (e.g., energy cost futures). Additionally, over 100 internal variables were considered, ranging from price quotes to time taken to close specific steps of the sales process. Three years of historical data were available from most data sets for training. Random forest and time series models were found to be the most effective.

- Define target market segments, forecasting objectives, and accuracy targets.

- Identify data sets, ingest at least 24 months of data for each variable, and process/clean data.

- Train algorithms using 70% of historical data and test them using 30% of historical data.

- Evaluate algorithm accuracy under known conditions and resilience under new conditions.

- Modify business processes to integrate algorithm output into forecasting analysis.

Results

- A set of highly predictive variables were prioritized for each target market out of 1,500+ variables assessed.

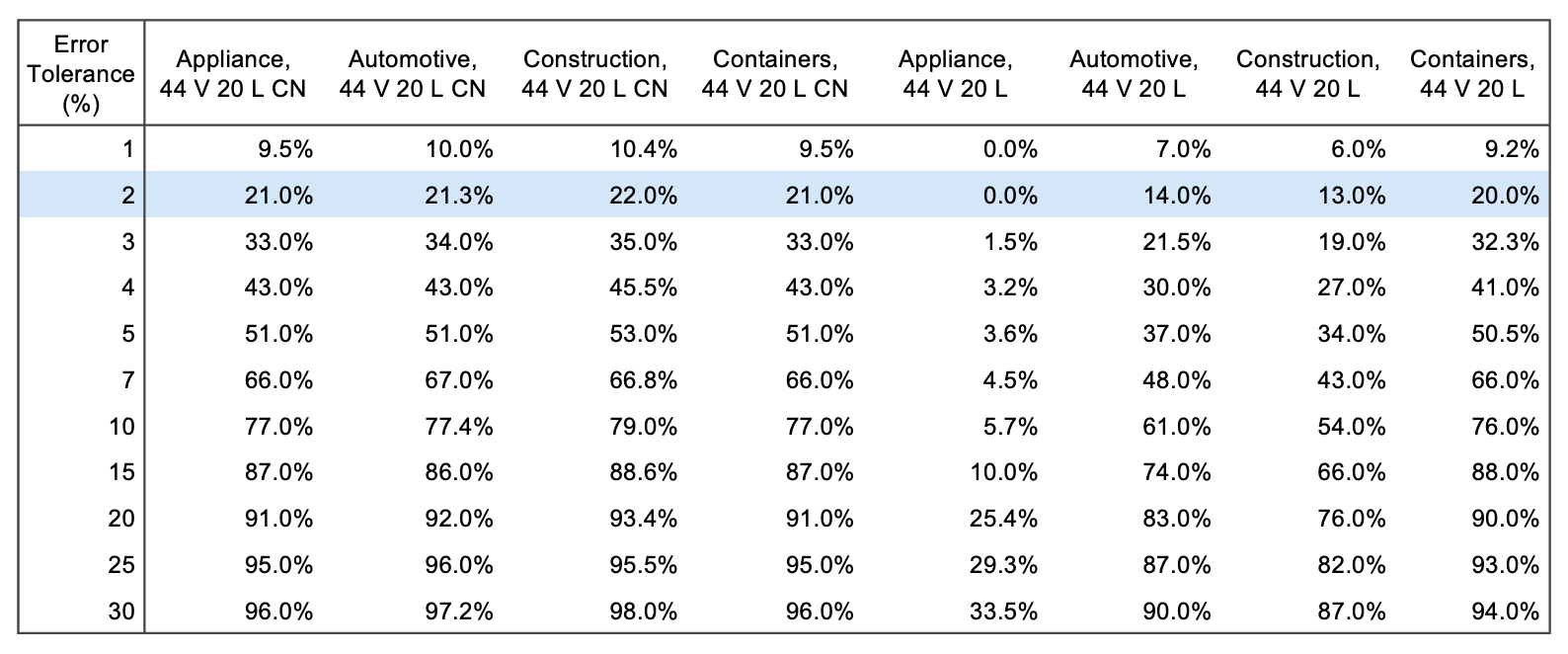

- The algorithm reached 95% accuracy to a +- 5% tolerance level in the 2-month and 3-month forecasting scenarios, surpassing the internal accuracy benchmark. The algorithm proved more accurate than internal forecasts under approximately 70% of sample forecasts. A collaborative human-ML approach was identified to improve outcomes.

- Continuous improvement efforts were defined, including improving data collection processes, assessing additional data sets, and building the historical training data set to encompass new market conditions that were not captured in the existing data set.