- Analytics & Modeling - Computer Vision Software

- Analytics & Modeling - Process Analytics

- Analytics & Modeling - Real Time Analytics

- Functional Applications - Remote Monitoring & Control Systems

- Sensors - Camera / Video Systems

- Electronics

- Discrete Manufacturing

- Quality Assurance

- Track & Trace of Assets

- Visual Quality Detection

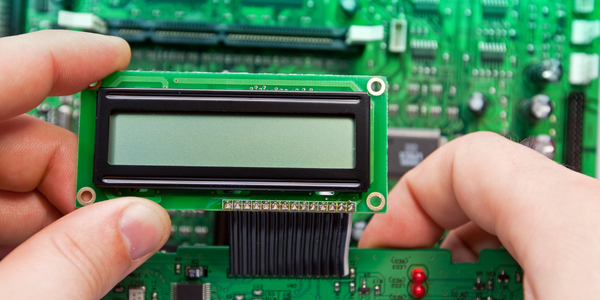

Shimane Fujitsu, a wholly-owned subsidiary of Fujitsu and a leading manufacturer of business notebooks and tablets, set out to improve processes where factory inspections found product errors. Prioritizing product rework based on shipping date was challenging, and it caused Shimane Fujitsu to incur additional shipping fees. The company needed a way to collect data to better track the location of products in the rework cycle as well as monitor progress in real time. The collected data would also help process analysis for future improvements.

Fujitsu Group and Intel jointly developed a solution using the Fujitsu Cloud Service IoT Platform and Intel IoT Gateway products. Phase 1 involved using IoT sensors on products identified for rework. The solution provides a visual map of the network area, including information about each product's location and status. With Fujitsu's distributed service platform technology, large volumes of sensor data can be processed in real time through a production information control system. Phase 2 of the pilot, which is ongoing, involves collecting video images of the inspection process for later analysis to provide a better understanding of why errors associated with rework products sometimes cannot be reproduced.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.